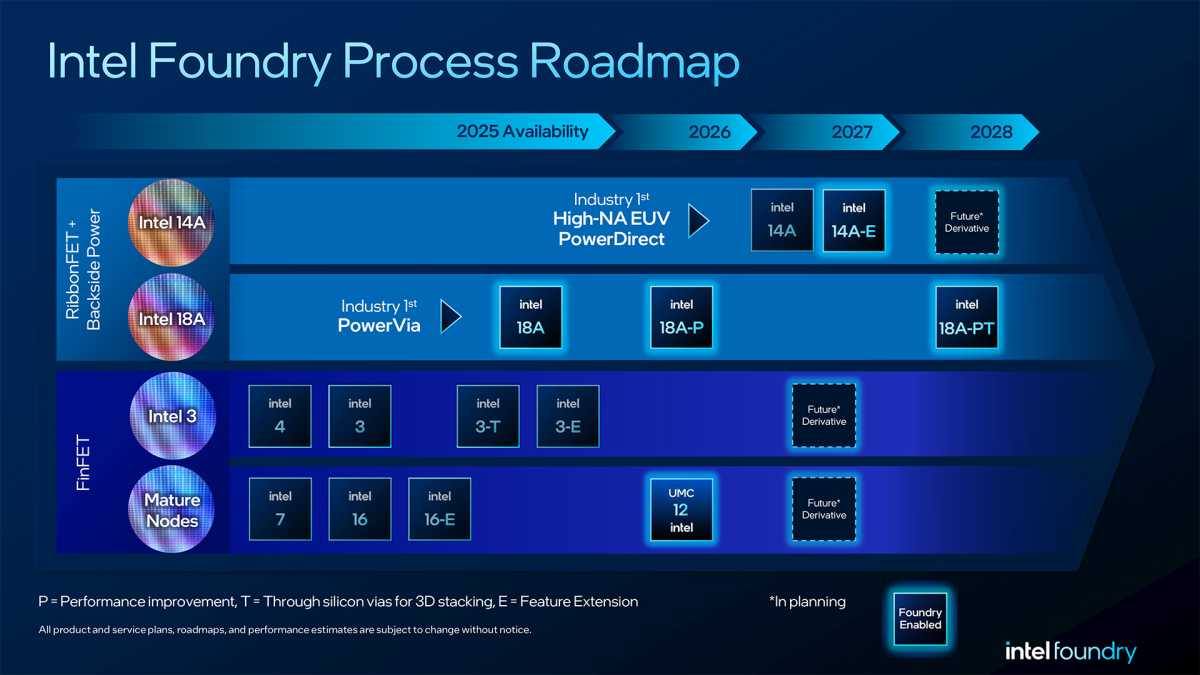

Intel said Tuesday that the company’s Arizona fab has run the first lots of the company’s Intel 18A wafers, the manufacturing technology powering its Panther Lake chips, while announcing a high-performance derivative process. Intel also offered a sneak peek at its 14A process, the next-generation manufacturing technology, which will include “turbo cells” for faster clock speeds.

Intel made the announcements at its Foundry Direct Connect symposium on Tuesday, as the company tries to convince Wall Street and its customers that its manufacturing processes are back on track.

Despite Intel executives’ on-stage promotion of their foundry roadmap, the products consumers will purchase directly influence Intel’s process roadmap. Intel’s upcoming Panther Lake processors will be manufactured on Intel’s 18A process node, completing the “five nodes in four years” goal that former chief executive Pat Gelsinger laid out. Intel’s next-gen 14A should be the technology Intel uses to fabricate “Nova Lake,” due in 2026.

Intel has used foundry partner TSMC to fabricate many of the tiles found within its disaggregated processors like Lunar Lake, and bringing that production in-house will save Intel money as well as demonstrate to customers that it can compete with TSMC.

Intel chief executive Lip-Bu Tan has said previously that Intel 18A is now in “risk production” and will reach volume production this year. Intel 18A includes technologies like RibbonFET, a next-gen “gate all around” transistor, as well as PowerVia, a backside power delivery architecture that can nudge up power performance by 4 percent. Intel 18A is “ready for full product design start” — just another way that Intel is saying that it’s ready to go.

Intel

On top of the generic 18A process, Intel has now added two new variants: what it calls 18A-P, designed for “enhanced performance” to a small subset of customers; and 18A-PT, which “builds on 18A-PT performance and power efficiency variants.” Early wafers based on Intel 18A-P are in the fab now, the company said. Intel 18A-PT can be connected to the top die using Foveros Direct 3D with a hybrid bonding interconnect pitch of less than 5 micrometers, Intel said in a statement.

Intel 14A, by contrast, improves upon PowerVia with a new technology called PowerDirect, its second-gen power delivery network. RibbonFET 2 will also improve upon RibbonFET, Intel said. Intel was supposed to move next to an intermediary 20A process but cancelled it.

The most intriguing part of the new 14A process may be something called “turbo cells,” which Intel refers to as a “boosted cell technology.” It will further enhance speed (including CPU maximum frequency and GPU critical paths) when paired with RibbonFET 2, Intel said. That might be key, as Intel and other chipmakers continually struggle with how to improve chip performance.

“Turbo Cells allows designers to optimize a mix of more performant cells and more power-efficient cells within a design block, enabling a tailored balance between power, performance, and area for target applications,” Intel said. It will be combined with High Numerical Aperture (High NA) EUV technology for smaller process features.

Intel 14A and Intel 18A-PT dies can be packaged together, Intel added, using Foveros Connect 3D stacking and embedded multi-die interconnected bridging, or EMIB. Intel is also announcing EMIB-T for future high-bandwidth memory needs as well as two additional Foveros derivatives, Foveros-R and Foveros-B.

Chcete-li přidat komentář, přihlaste se

Ostatní příspěvky v této skupině

For a decade or so, a major threat to your laptop wasn’t a virus, mal

Far be it from me to engage in a little schadenfreude… Actually, no.

During the first quarter of 2025, the total number of DDoS attacks in

One of the best ways to sync your smart lights with the images on you

Roku is best known for its streaming boxes and sticks, but it also of

If you’re ready to upgrade your PC experience while gaming or working